In 2025, AR is reshaping factories: speeding assembly, guiding maintenance, accelerating training, enabling remote support, and strengthening quality control. By delivering the right guidance at the right moment, it reduces errors, shortens downtime, improves safety, and empowers frontline users.

What Is Augmented Reality in Manufacturing

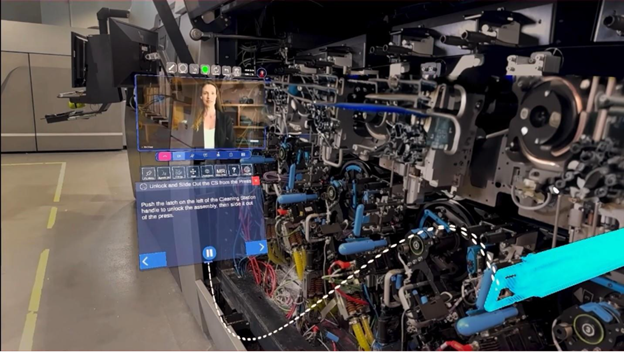

Augmented reality lets factory workers see helpful 3D interactive step-by-step guides, data, and warnings placed over real machines while they work. Cameras, sensors, and software line up these overlays, making complex tasks faster, safer, and easier.

Defining AR & How it Overlays Digital Information

Augmented reality (AR) is a technology that overlays digital information onto the physical world, blending virtual elements with a user’s real-time view of their surroundings. In a manufacturing context, this means a worker looking at a piece of machinery can see a digital schematic, step-by-step instructions, or real-time data projected directly onto the equipment itself.

This is achieved through AR-enabled devices that use cameras and sensors to recognize the environment and precisely place digital annotations. The goal is to provide workers with hands-on information without interrupting their workflow, thereby improving accuracy, efficiency, and safety.

AR Tools

AR tools can be divided into two main parts: hardware and software. Hardware refers to the devices used to experience augmented reality, while software is the backbone of those devices, making augmented reality possible.

Smart Glasses, Tablets, and Phones

Smart glasses, such as the new HMS SiNGRAY G2 and Magic Leap II headsets, are particularly useful in manufacturing as they enable hands-free operation while displaying critical data directly in the user’s field of view. This is a significant advantage in complex assembly or maintenance tasks.

Handheld devices like tablets and phones are also widely used, with mobile AR applications allowing workers to visualize 3D models and access information on the go.

The newly launched HMS SINGRAY G2 now comes with frontline.io pre-installed, delivering instant access to interactive 3D training, real-time support, and onboarding tools right out of the box. This integration empowers users to get up to speed faster with minimal downtime, no setup required. Explore the announcement

AR Software

AR software platforms provide the essential technology for AR hardware, enabling them to deliver digital content and guided instructions to users. For example, when it comes to enterprise industrial training and remote support, frontline.io provides a no-code XR platform that brings experts into the work area without the need for travel.

A remote specialist can watch the technician’s camera feed, drop AR markers onto the image, share a schematic in a split-screen view, or open an interactive Digital Twin so both sides are literally pointing at the same 3-D part.

These sessions stream through any modern browser or mobile app, so the same workflow runs on shop-floor tablets, office PCs, or head-mounted displays, making help available wherever the job happens.

By resolving issues in real time, teams typically record more first-time fixes and cut down on expensive site visits. Every call is captured as a searchable flow, turning ad-hoc advice into repeatable training material and helping newer staff close skill gaps faster. The net effect is fewer production delays, lower service costs, and a steady transfer of know-how from seasoned engineers to the next wave of technicians.

Another example is, FactoryOptix, is an industrial automation platform that integrates AR capabilities to enhance how workers interact with complex systems on the factory floor. It enables the visualization of real-time data, digital work instructions, and machine states directly within the user’s physical environment. Designed to support the entire workflow (from design and testing to deployment) FactoryOptix allows teams to build and scale industrial visualization applications that streamline operations, improve situational awareness, and reduce the cognitive load on frontline workers.

Moreover, Kit-AR focuses on augmented quality assurance, helping manufacturers reduce the “Cost of Poor Quality” by guiding workers through best-practice procedures and using AR-driven verification to catch errors in real time. Its solution enhances assembly accuracy, improves traceability, and ensures quality standards are consistently met on the shop floor.

Difference from VR and why AR fits the factory floor

While AR and VR are often linked, their key difference explains AR’s manufacturing edge. VR replaces the real world with a fully computer-generated environment via a vision-blocking headset, ideal for training simulations or virtual prototyping, ideal for applications like a flight simulator for pilot training.

In contrast, AR overlays digital information onto the real world so workers remain aware of their surroundings while getting critical data. For example, AR smart glasses can highlight faulty components on an assembly line, allowing for faster inspection. On the factory floor, where safety, situational awareness, and interaction with machinery and colleagues matter, AR’s enhancement rather than replacement of reality makes it a more practical, safer choice.

Key Use Cases in the Factory

Augmented Reality in manufacturing is not a futuristic concept; it is a practical tool already being implemented to address critical challenges and drive significant improvements in productivity, quality, and safety. Its ability to provide contextual, hands-on guidance makes it uniquely suited for the factory floor.

Immersive Training

Augmented reality is transforming factory floor training by replacing static manuals with dynamic, hands-on experiences. By overlaying digital instructions and safety warnings onto real-world equipment, AR acts as a “digital mentor” for both new and experienced employees.

This immersive method creates a safer and more efficient learning curve, allowing workers to practice complex tasks without risking damage to machinery or causing delays. The result is improved knowledge retention, faster onboarding, and a more agile workforce that can quickly adapt to new technologies.

Example: At Ford’s Rawsonville Components Plant, engineers set up a Microsoft HoloLens, powered AR simulation lab on the battery‐production line, projecting step‐by‐step instructions, safety graphics, and task sequences directly onto the real equipment.

Within months, approximately 30% of operators trained via AR hit full production cycle time within three or four parts cutting what used to be a three‐day ramp-up down to mere minutes of practice. Supervisors no longer need to shadow each new hire for days, freeing them to drive broader process improvements and slashing costly onboarding downtime.

Maintenance, Repairs, and Remote Expert Support

AR’s hands-free nature makes it a perfect fit for maintenance and repair tasks. A technician can use an AR device to see a digital overlay of a machine’s internals or diagnostic information, all without ever having to put down their tools.

This capability is further enhanced by remote expert support, where an on-site technician can connect with a subject matter expert anywhere in the world. The expert can see exactly what the technician sees through the AR device and provide real-time guidance by annotating the technician’s view with virtual arrows, circles, and notes.

This capability drastically cuts down on travel costs, reduces equipment downtime, and ensures even the most complex issues are resolved quickly and accurately.

Digital parts catalog complements maintenance workflows by giving technicians an interactive, visual view of assemblies with precise part numbers, specs, and live availability. With fast search and filters, cross-platform access, and integrations to systems like ERP/MES/PLM, teams can identify the right component on the first try, create pick lists, and place orders from the floor. Easy updates keep information current and aligned with CAD and service docs — reducing misorders, speeding repairs, and maximizing uptime.

Example: HP and frontline.io’s four-year collaboration has reshaped xRServices for industrial printers. Using frontline.io, HP now deploys support and training content 5x faster across global teams and resolves more issues remotely, cutting travel and supporting carbon-reduction goals. Average resolution times on remote calls have improved, boosting machine availability and uptime. Immersive XR guidance also speeds onboarding and helps operators work more independently, fueling the rapid growth of HP’s xRServices program.

Quality Control and Visual Inspection

Maintaining high-quality standards is essential. AR boosts quality control and visual inspections by adding precision. During an inspection, AR overlays a 3D model of the intended design onto the physical product, instantly revealing defects or discrepancies.

Workers can spot missing parts, incorrect placements, or surface flaws more easily. AR also guides inspectors through a standardized checklist with visual cues to confirm each step, reducing human error in repetitive tasks and ensuring products meet strict quality standards before leaving the factory.

Example: Volvo Group produces over 13,000 engine versions, each requiring 40 checks and up to 200 quality steps in just 8 minutes. By layering 3D CAD images directly on the engine and providing clear, on-screen instructions, they cut the QA process from more than a full day to under one hour (a 90% faster process) and trimmed new-operator training time by 60%, saving over $1,000 per station each year.

AR-Guided Assembly and Onboarding

Complex assembly tasks, often involving hundreds or even thousands of steps, are a prime application for AR. Instead of relying on static, paper-based manuals or PDFs, workers can wear smart glasses or use a tablet to see digital, step-by-step instructions overlaid directly onto the components they are working with.

This visual guidance can include highlighting where a part goes, what tool to use, and the correct torque specifications. This not only reduces human error but also drastically speeds up the learning curve for new employees. Challenges and Considerations for Adoption

Example: At Lockheed Martin, technicians assembling NASA’s Orion spacecraft wear Microsoft HoloLens 2 headsets that overlay holographic, step-by-step wiring and fastener instructions directly onto the vehicle’s adapter fairings.

This AR guidance cut what used to require an eight-hour shift down to just 45 minutes for marking and installing over 57,000 fasteners, while delivering zero assembly errors over two yearss.

Onboarding new employees also became dramatically faster: training time was reduced by 85%, getting recruits up to speed far quicker than with paper manuals.

Challenges and Considerations for Adoption

While the benefits of augmented reality (AR) in manufacturing are clear, companies should still plan thoughtfully — especially around integration, workflow design, and workforce adoption. Addressing these considerations proactively is crucial for a smooth transition to an AR-enabled factory floor.

Device strategy and Integration with Existing Systems

To successfully transition to an AR-enabled manufacturing facility, it’s crucial to have a clear strategy for devices and software, as well as a plan for integrating with your current systems. A well-planned strategy can help you get started and scale effectively.

Device Strategy and Software Licensing

Rather than budgeting for expensive, specialized hardware from day one, most companies can begin with existing iOS/Android devices and expand as needs grow. Smart glasses can be added later for hands-free scenarios once the use cases are proven. Software subscriptions should scale with usage, and a pilot or limited deployment can validate ROI before broader rollout. A focused cost-benefit analysis should center on expected gains in efficiency, quality, and safety — not on large capital expenditures.

frontline.io’s device-agnostic platform supports a wide range of devices, from standard smartphones and tablets to various smart glasses, allowing companies to choose the best hardware for their specific needs without being locked into a single vendor, and it offers flexible licensing models that scale from pilot to full deployment.

Seamless Integration with Legacy Systems

Many manufacturing facilities operate on a foundation of legacy systems, including older Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). Integrating new AR technology with these existing platforms is a complex and often costly challenge.

The new AR software must be able to securely and reliably communicate with these systems to pull and push critical data, such as work orders, CAD files, and real-time machine performance data. This often requires custom development and middleware solutions, adding to the overall cost and complexity of the project. A failure to achieve seamless integration can lead to data silos, workflow interruptions, and ultimately, a failed AR implementation.

frontline.io simplifies this process with a flexible, low-code integration framework that connects with legacy systems and databases, eliminating the need for extensive custom development and reducing implementation time and cost.

Ensuring data security and privacy

Using augmented reality in manufacturing requires gathering and processing large volumes of data (proprietary processes, real-time operations, and sensitive employee details) raising security and privacy concerns.

To mitigate risks of cyberattacks, breaches, or IP theft, companies must deploy strong encryption, secure networks, and strict access controls. Clear policies on data ownership, usage, and storage are essential to comply with privacy laws and maintain employee trust. For Example, frontline.io offers both cloud and on-premise deployment options to meet security and data-residency requirements, and the platform is SOC2-certified.

The importance of user training and adoption

Technology is only as effective as the people who use it. The successful adoption of AR in manufacturing hinges on comprehensive user training and a strategy to overcome employee resistance to change.

Overcoming Resistance to Change

Introducing a new technology like AR can be met with skepticism and resistance from workers who are accustomed to traditional methods. Concerns about job security, the complexity of new tools, and the fear of being monitored can create friction.

A successful rollout requires transparent communication, involving employees in the planning process, and clearly articulating the benefits of AR, such as improved safety and reduced workload. Highlighting AR can make their jobs easier and more efficient is key to gaining buy-in.

Comprehensive Training Programs

Effective AR adoption hinges on comprehensive and ongoing training. A one-off session is insufficient. Training programs should not only cover how to use the AR hardware and software but also teach workers how to interpret digital information and incorporate it into their daily workflows.

This training should be tailored to different skill levels and job functions, ensuring that every user is comfortable and proficient. Investing in a continuous training program is crucial for maximizing the return on investment and ensuring that the technology is used to its full potential. As part of this, frontline.io provides onboarding for all customers and always-available support to assist teams throughout deployment and day-to-day operations.

frontline.io XR Capabilities for Industrial Manufacturing

Effective AR adoption hinges on comprehensive and ongoing training. A one-off session is insufficient. Training programs should not only cover how to use the AR hardware and software but also teach workers how to interpret digital information and incorporate it into their daily workflows.

This training should be tailored to different skill levels and job functions, ensuring that every user is comfortable and proficient. Investing in a continuous training program is crucial for maximizing the return on investment and ensuring that the technology is used to its full potential. As part of this, frontline.io provides onboarding for all customers and always-available support to assist teams throughout deployment and day-to-day operations.

The Power of Digital Twins

Central to the frontline.io platform is its ability to rapidly convert a manufacturer’s existing CAD files into interactive 3D digital twins. This proprietary technology can render over 200,000 parts and create optimized, interactive models in less than 10 minutes. This eliminates the lengthy and expensive modeling timelines that often serve as a barrier to adopting AR training.

This capability is particularly valuable for industries where equipment is complex and highly detailed. frontline.io’s digital twin technology is designed for sectors such as aerospace, defense, medical devices, semiconductors, and printing, enabling hands-on, scenario-based learning without requiring physical equipment.

Fast Track Pro

Fast Track Pro is a feature in the frontline.io app that allows you to turn CAD files into fully functional Digital Twins without leaving the platform. Instead of switching between different tools, you can import your design files directly into the app and get them ready for use in training, support, or marketing in just a few steps. This makes the process faster, easier, and more consistent.

Once your CAD file ismported, Fast Track Pro gives you simple tools to adjust and prepare it. You can merge several models into one scene, remove or duplicate parts, rearrange components, and even slice models to focus on specific areas. All of this happens inside the same app, so you can go from a raw CAD file to an AR-ready Digital Twin without extra software or complex workflows.

Cross-Device Accessibility

frontline.io is device-agnostic meaning it runs seamlessly on smartphones, tablets, laptops/PCs, and XR headsets (AR/VR smart glasses), allowing learners to train wherever and however they work best. This cross-device accessibility removes physical and technological barriers, helping organizations save an average of 50% on travel costs and machine hours, making immersive training both practical and cost-effective.

Real-World Impact

The effectiveness of the frontline.io platform is best demonstrated through its successful implementation in diverse industries. The company’s work with global leaders showcases the tangible benefits of its AR and digital twin technology.

HP Inc.

In the printing industry, HP Inc. utilized frontline.io to revolutionize the way it trains engineers on complex printing systems. By creating immersive simulations from its own CAD data, HP achieved a remarkable 5x acceleration in the creation and deployment of XR content.

This agility allowed the company to swiftly adapt training materials in response to new product lines and evolving service requirements, ultimately improving efficiency and reducing the time needed to bring new engineers up to speed.

Sheba Medical Center

Although outside traditional manufacturing, Sheba Medical Center’s use of frontline.io showcases its versatility and power. The center trained staff on complex heart and liver procedures using detailed 3D anatomical models, virtual cuts, and guided discussions.

As a device-agnostic platform, it seamlessly connected global participants, transforming consultations and training into immersive experiences. This case proves how frontline.io’s rapid 3D model generation and cross-device accessibility enable hands-on, high-fidelity training across many fields.

Revolutionizing Medical Training at Sheba Medical Center with frontline.io

Discover how Sheba Medical Center — consistently ranked among the world’s top hospitals — leveraged frontline.io’s 3D Digital Twin platform to turn complex medical consultations into immersive, interactive experiences, enabling global teams to visualize anatomy in true-to-life detail, perform virtual cuts, and collaborate seamlessly across any device.

Read the Full Case Study

As manufacturing continues to evolve, augmented reality in manufacturing is no longer a futuristic fantasy but a fundamental driver of efficiency, quality, and safety on the factory floor. By delivering contextual, hands-on information directly to workers, AR tools are bridging the skills gap, minimizing errors, and accelerating everything from assembly to maintenance. Looking ahead, the integration of AR with technologies like digital twins and analytics will only deepen its impact, creating smarter, more resilient, and more productive manufacturing ecosystems ready to meet the complex demands of tomorrow.

Bibliography

- Number Analytics. (2025, June 23). AR in Manufacturing: Use Cases. https://www.numberanalytics.com/blog/ar-use-cases-in-manufacturing

- Boland, M. (2025). Case Study: Volvo Elevates Quality Assurance with AR. AR Insider. Retrieved from https://arinsider.co/2025/03/04/case-study-volvo-elevates-quality-assurance-with-ar/

- Scimeca, Dennis. 2025. “Augmenting Reality at Ford Motor (Video).” IndustryWeek, March 12, 2025. https://www.industryweek.com/technology-and-iiot/iiot/article/55274112/augmenting-reality-at-ford-motor-video.

- Langston, Jennifer. “To the Moon and Beyond: How HoloLens 2 Is Helping Build NASA’s Orion Spacecraft.” Microsoft Source, September 22, 2020. https://news.microsoft.com/source/features/innovation/hololens-2-nasa-orion-artemis/

- Microsoft Azure. “Mixed Reality Momentum: HoloLens 2 Expands Globally and New Azure Service Launches.” Microsoft Azure Blog, September 24, 2020. https://azure.microsoft.com/en-us/blog/mixed-reality-momentum-hololens-2-expands-globally-and-new-azure-service-launches/

- Boland, Mike. “Case Study: Building Spaceships with AR.” AR Insider, September 13, 2022. https://arinsider.co/2022/09/13/case-study-building-spaceships-with-ar/